In the previous post, we examined a possible set of features and design goals for such a device. However, the feature set and design goals are difficult to implement. So here’s idea #2. The design is greatly simplified and has less feature. However, it should be much simpler to make.

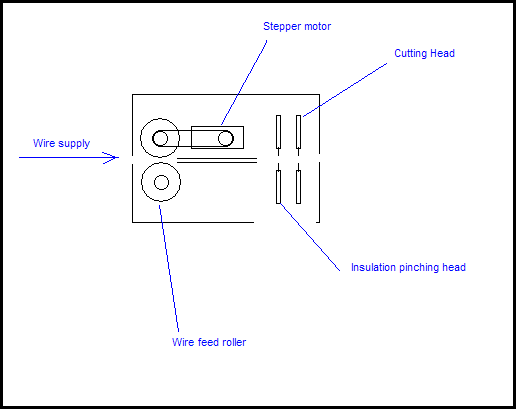

The device will consist of a set of wire feed rollers, a wire cutter and a wire insulation stripper head. Since it is difficult to design a device that will fully remove the insulation off of the end of the wire, this design will not incorporate such a feature. Instead, this design will use the insulation stripper head to pinch (effectively cut) the insulation near the end where it should be stripped off. After it has pinched both sides, the cutting head will cut the wire. The wire will fall out and is almost ready for use. However, the insulation has not been stripped from the end; it has only been pinched. It is now very easy to remove the insulation by hand with your fingernail since it has already been cut. Here is a diagram of the design:

How it works:

- Wire is fed into the wire feed rollers. The wire then goes into the thin tube in the middle which aligns the wire properly.

- The wire is further rolled out until it reaches the insulation pinching head. At this point, a little more wire is pushed out (about 5 mm) so that the insulation can later be stripped off.

- The cutting head then does its job by pinching the insulation so it can be pulled off easily by your fingernail.

- More wire is fed. The amount that is fed is equal to the desired length of the wire.

- Once the desired length of wire is fed, the insulation pinching head once again pinches the wire.

- Now more wire is pushed so it can advance to the cutting head. The cutting head finally cuts the wire (end product) which then drops out of the machine.

This design is a lot simpler because it requires a lot less parts. Stepper motors and motor drivers can be found anywhere. The insulation pinching head can be acquired by dismantling a hand-operated wire cutter which can be found anywhere as well. The cutting head can be made out of anything – even cheap wire cutter pliers if desired.

The whole device can be controlled by direct connection to a computer or by a PIC microcontroller.

I like this.

ReplyDeleteIt is similar to a wire cutter designed by the production manager at Datapoint Corp. This one is capable of being controlled by a PLC or a PIC.

Do you have a link to their product/design?

ReplyDelete